Guar gum is a natural polysaccharide derived from the seeds of the guar plant (Cyamopsis tetragonoloba), and its extraction process is crucial in determining its quality and usability across various industries. The extraction process involves several stages that refine the raw guar seeds into a usable gum powder. Understanding this process is essential for appreciating how guar gum is utilized in diverse applications. This article explores the guar gum extraction process and the types of ingredients that can be applied using guar gum powder.

Guar Gum Extraction Process

1.1. Harvesting and Cleaning

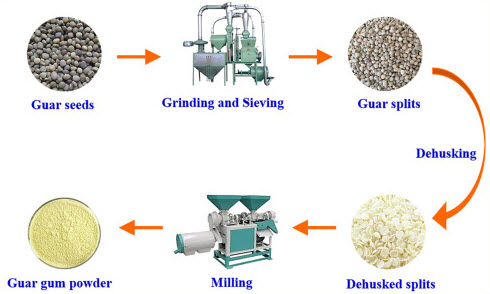

The extraction process begins with the harvesting of guar seeds, which are typically collected from the guar plant once the pods are fully mature. The seeds are then cleaned to remove any extraneous materials such as dirt, stones, and plant debris. This step is essential to ensure the purity and quality of the guar gum powder.

1.2. De-Husking and De-Germing

After cleaning, the guar seeds undergo de-husking and de-germing. The outer husk and inner germ are removed through milling and screening processes. This step isolates the endosperm, the part of the seed that contains the valuable polysaccharides needed to produce guar gum. De-husking and de-germing are critical for obtaining high-quality guar gum powder.

1.3. Grinding and Milling

The endosperm is then ground into a fine powder. This milling process reduces the particle size and ensures a uniform consistency of the guar gum powder. The grinding process must be carefully controlled to achieve the desired particle size and to maintain the functional properties of the guar gum.

1.4. Hydration and Purification1.4. Hydration and Purification

To enhance the functionality of the guar gum powder, it is often subjected to hydration and purification processes. During hydration, the guar gum powder is mixed with water to form a gel-like consistency. This step helps in removing any residual impurities and in achieving the desired viscosity and consistency.

1.5. Drying and Packaging

After hydration and purification, the guar gum solution is dried to obtain the final powdered form. The drying process must be carefully controlled to prevent degradation of the polysaccharides. Once dried, the guar gum powder is packaged and ready for distribution.

2. Types of Applicable Ingredients

Guar gum powder is highly versatile and finds applications in various food and non-food industries.

2.1. Food Processing

- Beverages: Guar gum is used as a thickening and stabilizing agent in beverages such as fruit juices, smoothies, and flavored waters. It helps to maintain a uniform texture and prevents the separation of ingredients.

- Bakery Products: In bakery products like bread, cakes, and cookies, guar gum improves texture, moisture retention, and shelf life. It enhances the softness and consistency of baked goods.

- Dairy Products: Guar gum is used in dairy products such as ice cream, yogurt, and cheese to improve texture and stability. It helps in achieving a smooth and creamy consistency.

- Sauces and Dressings: In sauces, dressings, and gravies, guar gum acts as a thickening agent, providing the desired viscosity and preventing separation of ingredients.

2.2. Pharmaceuticals

- Tablets and Capsules: Guar gum is used as a binder and disintegrant in pharmaceutical formulations. It helps in controlling the release of active ingredients and improving the overall stability of tablets and capsules.

- Topical Products: In topical pharmaceuticals, guar gum serves as a thickening agent, providing the desired consistency and stability in gels and creams.

2.3. Oil and Gas Industry

- Drilling Fluids: Guar gum is employed in hydraulic fracturing (fracking) fluids to increase viscosity and carry proppants into fractures. It plays a crucial role in enhancing the efficiency of oil and gas extraction processes.

2.4. Textile Industry

- Printing Pastes: In textile printing, guar gum is used in printing pastes to improve the viscosity and consistency of the ink. It ensures even distribution and enhances the quality of textile prints.

2.5. Personal Care and Cosmetics

- Skincare Products: Guar gum is utilized in personal care products like lotions, creams, and shampoos as a thickening and emulsifying agent. It helps in achieving the desired texture and stability of cosmetic formulations.

Conclusion

The extraction process of guar gum involves careful handling of the seeds to ensure the production of high-quality gum powder. Understanding the various stages of extraction—from cleaning and de-husking to grinding and drying—helps in appreciating the functional properties of guar gum. Its wide range of applications across food processing, pharmaceuticals, oil and gas, textiles, and personal care underscores its versatility and importance in modern industries. By mastering the extraction process and application techniques, manufacturers can effectively harness the benefits of guar gum powder in their respective fields.